|

Sculpteo 3D Printing Material ExperienceWe have been using Sculpteo's 3D printing service to produce parts that we desire with great success. In this article, we want to document our experience with the handling of various materials that we printed through Sculpteo. MulticolorThe multicolor 3D printed material is nice for models that are colorful. However, it is hard and brittle. If you apply force to it, it will crack and break apart. It's great for decorations and models that is free of stress. It's not so good for mechanical parts that needs to be screwed or tied down (stress).

The above photo is an example of multicolor parts. It has a matte texture surface that feels like sandstone when you touch it. Red Polished PlasticSculpteo sent us this red alien model (see photo below). It is 3D printed out of red polished plastic. It's characteristic is very similar to the while raw plastic (see section below). The plastic is bendable and not brittle.

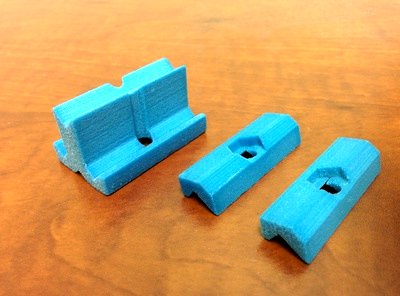

The alien character is just too cute for us to cut into it or experiment with it. White Raw PlasticWe printed with the white raw plastic the most, because it is the strongest material, based on Sculpteo's FAQ. The white raw plastic has a matte texture surface that reminds us of sugar cubes. However, it doesn't crumble like sugar cube. The white material attracts dirt. Rubbing on it with our bare dirty hands turns the white plastic black, eventually. The following photo gives you an idea of the white raw plastic.

The white plastic is extremely resilient. It provides full strength at thickness greater than 3mm. At 2mm, it is bendable and flexible but does not break. Metal file does very little damage to it. It takes great effort to file away 1mm of material. Drilling requires torque. Once the drill bit has cut into the plastic, you really can't manipulate the depth like wood; it will completely drill through. The plastic is really tough, so the drill bit will grab onto the part. That means holding the part by hand is extremely dangerous; it can rip your hand. You must clamp the part down with a vise or clamps to drill it. Therefore, specialized holes should be modeled and printed, not drilled later on. The plastic can be cut with a hobby saw or a hack saw. Because of its resilience, cutting without downward force will result in smoothing/filing the cut. Therefore, to actually cut through the plastic, a decent amount downward force must be applied. The material can be painted quite easily with or without primer. It seems to absorb paint, therefore, it is readily paint-able at a wide range of temperature.

Attachments

|

Articles

|

Wiki

164 Users Online

|

|

Copyright © 2004 - 2026. All Rights Reserved. |